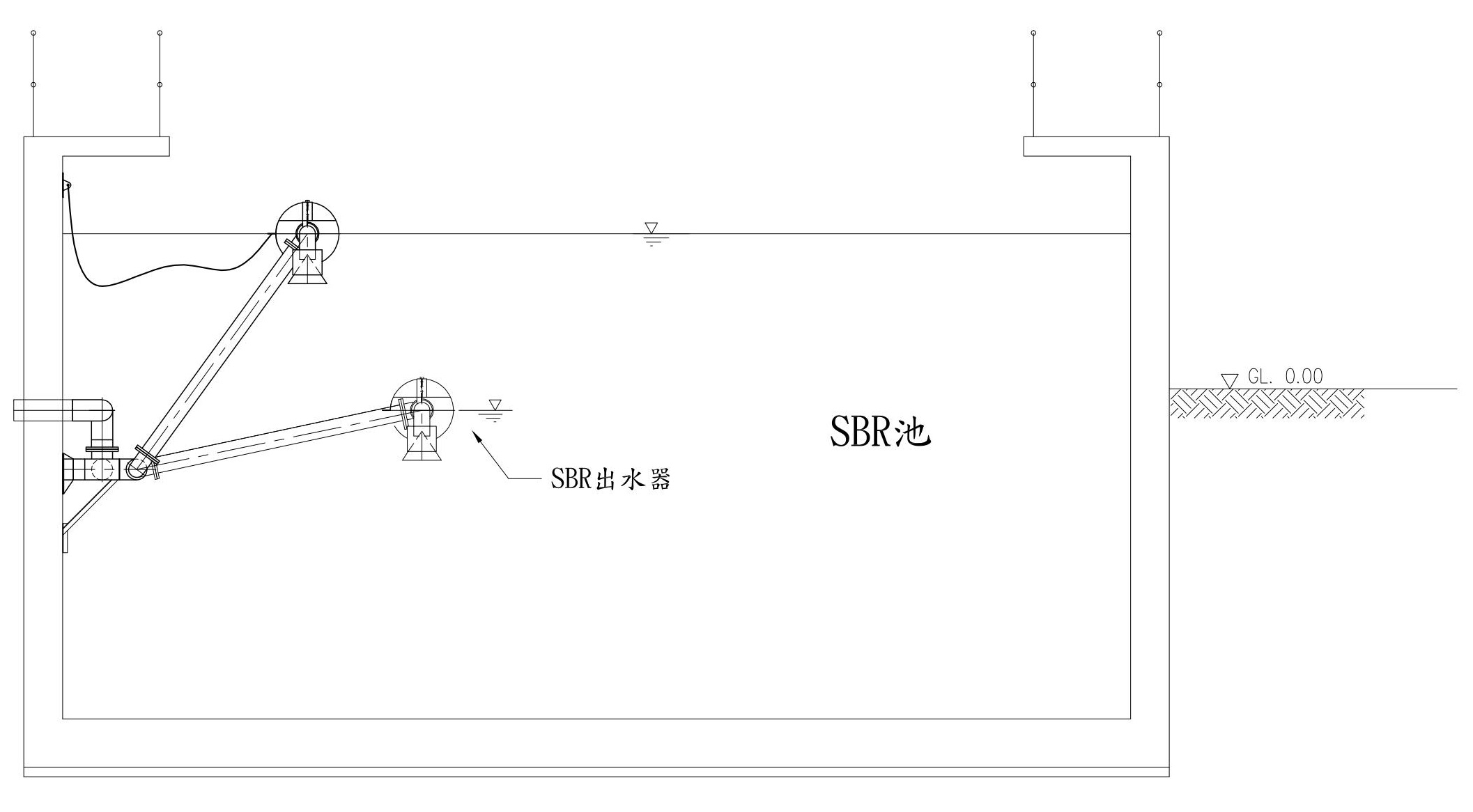

Floating discharge system of SBR tank

The batch activated sludge (SBR) process is an aerobic biological treatment method, an improved version of the traditional activated sludge method. The basic principle is similar to the conventional activated sludge aerobic process, only the continuous operations are changed to batch operations. The so-called aerobic treatment is that aerobic microorganisms use organic pollutants in wastewater as a source of nutrients for growth and proliferation, and these increased microorganisms are separated from wastewater by precipitation to obtain clean water after treatment.

SBR is a microbiological treatment method based on continuous treatment in traditional microbiology methods to apply batch treatment. The biggest advantage of SBR is that it can flexibly change the conditions in the processing technology without having to change any hardware devices and still achieve the desired effect. SBR operations are repetitive. , repeat periodically. Each cycle is traditionally divided into five stages: water supply, reaction, deposition, drainage and stillness.

Floating discharge systems for wastewater drainage are mainly used in wastewater treatment (SBR), the use of drainage by this method can reduce the amount of suspended solids (SS) in water and improve water quality. amount of water after treatment.

Feature

Discharging water in the SBR is done using a floating drain system. The system includes a floating filter - exhaust pipe - mesh and support equipment.

The float has the dual role of providing buoyancy to the drain pipe and preventing floating sludge from escaping. During the process, there is water supplied to the reaction tank, reaction, precipitation, the float is filled with air, the float floats on the surface of the wastewater in the tank. When drainage is needed, the liquid floating above will pass through the water intake port into the drainage pipe. The drainage system will be used again when the water level in the tank reaches the lowest water level.

Equipment is made of stainless steel (SUS304)

The device does not use power so it saves energy, does not vibrate and is noiseless.